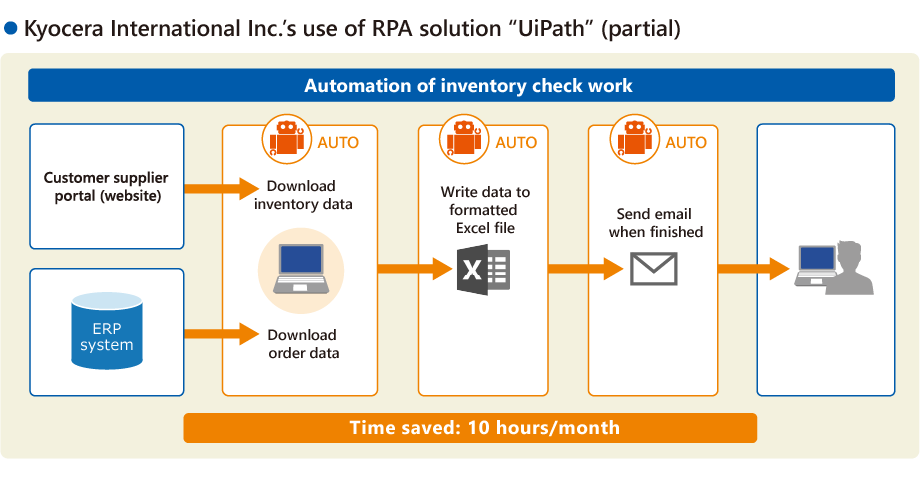

Kyocera International Inc.

Summary:

Introduced service:

Client interview

Why and how did you choose UiPath?

Suited to time-sensitive work, KDDI’s success gave confidence

Searching for a way to improve the productivity of the automotive components sales division, Divisional Vice President Kazumi Nishikawa began looking at RPA.

“RPA eliminates human error, and I was already interested in new technology. When I received an explanation from KDDI about how UiPath could raise productivity, I found UiPath to be well-suited to the automation of managing shipments and inventory, which require real-time updates.” As for his selection of KDDI and UiPath, Nishikawa said, “UiPath solutions can be shared amongst similar tasks, and KDDI’s global success with UiPath gave me confidence.”

Automotive Components Sales Division

MR.KAZUYOSHI NISHIKAWA

Results of using UiPath

Work that took about an hour now possible in 5 minutes

Automotive Components Sales Division

MR.KAZUOMI BABA

Through RPA, Kyocera International was able to greatly reduce its data entry workload. Product Development Manager Kazuomi Baba says, “Until now it took large amounts of time to check that massive amounts of data were being input without mistakes, but thanks to RPA it is now done accurately and quickly and the burden on the staff has been reduced. In America this type of work easily becomes a black box only understood by whoever is doing it, but with RPA we were able to lay out and visualize the process.”

Further efficiency through standardization

In preparation for sharing RPA solutions across tasks, Kyocera International standardized its shipment management forms. Mr. Baba says, “For sharing RPA solutions, we standardized our shipment management Excel files’ formats so that they could be used for multiple companies. Changes like this should reduce our workload burden going into the future.”

A stop to overwork and better use of human resources

Through the introduction of RPA, the Automotive Components Sales Division was able to cut about 10 hours of work per month. This has allowed it to take on new tasks without hiring new staff. Mr. Nishikawa says, “RPA had the effect not only of reducing the burden of routine work, but of allowing us to focus human resources on work with high added value.” He expressed his intention to continue the RPA journey, saying, “We would like to look at deploying the RPA solutions we have so far to similar tasks, and at whether RPA can be used in other divisions.”

Service implementation diagram

- *The listed information was from the date of the interview.